Content

- Predetermined Overhead Rate Calculator

- Financial Ratios

- The Formula for the Predetermined Overhead Rate

- Component Categories under Traditional Allocation

- 1 Calculate Predetermined Overhead and Total Cost under the Traditional Allocation Method

- Financial Accounting

- Accounting Topics

- Predetermined overhead rate

There are some things that are needed in order to figure out an accurate Predetermined Overhead Rate. The more historical data that a company has, the better off that they will be when computing predetermined rates. It is also possible for a company to use different methods depending on the specific products, processes, and services within the organization. In order to find the overhead rate we will use the same basis that we have chosen by multiplying this basis by the calculated rate. For example, if we choose the labor hours to be the basis then we will multiply the rate by the direct labor hours in each task during the manufacturing process. Are all costs other than direct material, direct labor, or selling and administrative costs.

- Therefore, you are required to calculate the predetermined overhead rate.

- The quickest way to review them is to list all expenses in descending dollar value order.

- In the coming year, the company expects the total overheads to be $100,000 and expects that there will be 25,000 machine hours worked.

- Without such a rate, a company looking to identify the actual cost of a project will have to wait for the project completion.

- A company that excels at monitoring and improving its overhead rate can improve its bottom line or profitability.

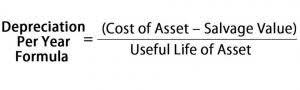

The rate is used to identify the expected costs of machine production, which allows the business to properly allocate the financial resources needed to ensure proper and efficient production and operations. Notice that the formula of predetermined overhead rate is entirely based on estimates. The overhead applied to products or job orders would, therefore, be different from the actual overhead incurred by jobs or products. The comparison of applied and actual overhead gives us the amount of over or under-applied overhead during the period which is eliminated through recording appropriate journal entries at the end of the period. Suppose GX company uses direct labor hours to assign manufacturing overhead cost to job orders. The company’s budget shows an estimated manufacturing overhead cost of $16,000 for the forthcoming year.

Finally, using a predetermined overhead rate can result in inaccurate decision-making if the rate is significantly different from the actual overhead cost. The overhead rate has limitations when applying it to companies that have few overhead costs or when their costs are mostly tied to production. Also, it’s important to compare the overhead rate to companies within the same industry. A large company with a corporate office, a benefits department, and a human resources division will have a higher overhead rate than a company that’s far smaller and with less indirect costs. If it is significant, it will have a huge impact on the financial statement.

Predetermined Overhead Rate Calculator

So, if you were to measure the total direct labor cost for the week, the denominator would be the total weekly cost of direct labor for production that week. Finally, you would divide the indirect costs by the allocation measure to achieve how much in overhead costs for every dollar spent on direct labor for the week.

This results in $50,000 being allocated to inventory in the period. A later analysis reveals that the actual amount that should have been assigned to inventory is $48,000, so the $2,000 difference is charged to the cost of goods sold. The rate is determined by dividing the fixed overhead cost by the estimated number of direct labor hours.

Financial Ratios

Establishing the overhead allocation rate first requires management to identify which expenses they consider manufacturing overhead and then to estimate the manufacturing overhead for the next year. Manufacturing overhead costs include all manufacturing costs except for direct materials and direct labor. Estimating overhead costs is difficult because many costs fluctuate significantly from when the overhead allocation rate is established to when its actual application occurs during the production process. You can envision the potential problems in creating an overhead allocation rate within these circumstances. The goal is to allocate manufacturing overhead costs to jobs based on some common activity, such as direct labor hours, machine hours, or direct labor costs. For example, if the annual budget is based on a production quantity of 10,000 units and the direct labor required for each unit is three hours, the total direct labor is 10,000 x 3 or 30,000 hours.

- A predetermined overhead rate is an allocation rate that is used to apply the estimated cost of manufacturing overhead to cost objects for a specific reporting period.

- The most common allocation bases are direct labor hours, direct labor costs, and machine hours.

- The management can estimate its overhead costs to be $7,500 and include them in the total bid price.

- •Predetermined rates make it possible for companies to estimate job costs sooner.

- Now, calculate the predetermined overhead rate for the departments listed above.

- Since the rate is based solely on estimates and not confirmed costs, the end results may not always match the actual manufacturing overhead rates.

Using a predetermined rate, companies can assign overhead costs to production when they assign direct materials and direct labor costs. Without a predetermined rate, companies do not know the costs of production until the end of the month or even later when bills arrive. For example, the electric bill for July will probably not arrive until August. If Creative Printers had used actual overhead, the company would not have determined the costs of its July work until August. It is better to have a good estimate of costs when doing the work instead of waiting a long time for only a slightly more accurate number.

Examples can include labor hours incurred, labor costs paid, amounts of materials used in production, units produced, or any other activity that has a cause-and-effect relationship with incurred costs. The predetermined overhead rate is found by taking the total estimated overhead costs and dividing by the estimated activity base. That probably makes little sense so let us look at a summary of steps and then apply it to an example. Overhead for a particular division, product, or process is commonly linked to a specific allocation base.

The Formula for the Predetermined Overhead Rate

Of course, management also has to price the product to cover the direct costs involved in the production, including direct labor, electricity, and raw materials. A company that excels at monitoring and improving its overhead rate can improve its bottom line or profitability. Let’s assume a company has overhead expenses that total $20 million for the period. The company wants to know how much overhead relates to direct labor costs. The company has direct labor expenses totaling $5 million for the same period. The equation for the overhead rate is overhead costs divided by direct costs or whatever you’re measuring.

- At the end of managerial accounting cycle, the difference between manufacturing overheads applied and actual manufacturing overheads is adjusted.

- The predetermined overhead rate calculation shown in the example above is known as the single predetermined overhead rate or plant-wide overhead rate.

- Musicality uses this information to determine the cost of each product.

- Also, it’s important to compare the overhead rate to companies within the same industry.

- Once a company determines the overhead rate, it determines the overhead rate per unit and adds the overhead per unit cost to the direct material and direct labor costs for the product to find the total cost.

- The company’s budget shows an estimated manufacturing overhead cost of $16,000 for the forthcoming year.

- This analysis is one of the most important aspects of cost accounting in any organization as it accurately identifies the reason for the change.

Second, the manufacturing overhead account tracks overhead costs applied to jobs. You saw an example of this earlier when $180 in overhead was applied to job 50 for Custom Furniture Company. Other examples of actual manufacturing overhead costs include factory utilities, machine maintenance, and factory supervisor salaries. All these costs are recorded as debits in the manufacturing overhead account when incurred.

Component Categories under Traditional Allocation

What makes this calculation important is that it provides a measurement of expense relative to a corresponding base. Imagine if you established an initial expense budget of $200,000, a payroll budget of $100,000 and a sales forecast of $400, with a targeted profit margin of $100,000 for the year. Then imagine experiencing a lower sales volume at $250,000 and, therefore, a lower production payroll at $75,000. If you’re still tracking expenses against a $200,000 budget, you may easily be deceived into thinking your spending is on track. However, in reality, $250,000 of sales less a $75,000 payroll and $200,000 of expenses would calculate to a $25,000 loss. I would like to ask how to determine the predetermine overhead rate for each departments. Plz can you explain me how to compute percentage of FOH which is based on direct labor.

Overhead costs applied to jobs that are less than actual overhead costs. A method of costing that uses a predetermined overhead rate to apply overhead to jobs. Dividing overhead costs by the number of hours your machinery is used gives you the basis of determining overhead rate machine hours.

1 Calculate Predetermined Overhead and Total Cost under the Traditional Allocation Method

Small companies tend to use activity-based costing, whereas in larger companies, each department in which different processes of production take place typically computes its own https://www.bookstime.com/. The formula for the predetermined overhead rate is purely based on estimates. Hence, the overhead incurred in the actual production process will differ from this estimate. A predetermined overhead rate is an allocation rate given for indirect manufacturing costs that are involved in the production of a product . The use of a predetermined overhead rate rather than actual data to apply overhead to jobs is callednormal costing. Because overhead is typically driven by direct labor hours in a service organization, direct labor hours or direct labor cost is the most common allocation base. Direct costs are so called because they can be directly attributed to manufacturing a single unit of the final product.

Allocation bases are known amounts that are measured when completing a process, such as labor hours, materials used, machine hours, or energy use. The more consistency there is between the total overhead and the allocation base, the more accurate the estimate of predetermined overhead will be.

As the term implies, a predetermined overhead rate is calculated before the actual production process begins. The idea is to make use of available historical data to project the factors that will apply to the process and how the activity will impact the inventory. Enter the total manufacturing overhead cost and the estimated units of the allocation base for the period to determine the overhead rate. Occurs when actual overhead costs are lower than overhead applied to jobs . The T-account that follows provides an example of overapplied overhead. Note that the manufacturing overhead account has a credit balance when overhead is overapplied because more costs were applied to jobs than were actually incurred.

Complete the job cost sheets for job number C40 (Round-off unit cost to the nearest cent and where necessary, show ALL relevant workings. N) 75% of the water tanks in job number C40 were sold on account during June for $750 each. I) The insurance cost covering factory operations for the Month of June was $2,500. H) June council rates and property taxes on the factory were paid in cash $2,370. To determine the amount of overhead to assign to each product line, following information are given. Who can explain for me the difference between over-applied overhead and under-applied overhead.

Does predetermined overhead rate include depreciation?

These costs are only incurred because of production, and they include items such as equipment and building depreciation, facility maintenance, factory utilities and factory supplies.

Such a system, while more complex, is considered to be more accurate. Since it can reflect differences across departments in how overhead costs are incurred.

Job 31 has a direct materials cost of $390 and a total manufacturing cost of $1,260. Overhead is applied to jobs at a rate of 200 percent of direct labor cost. The companies use different allocation bases when calculating their predetermined overhead rates. The predetermined overhead rate is used to price new products and to calculate variances in overhead costs. Variances can be calculated for actual versus budgeted or forecasted results. Pre-determined overhead rate based on machine operating hours equals total budgeted manufacturing overheads (of $1,000,000) divided by total budgeted machine operating hours . It gives us a pre-determined overhead rate of $10 per machine operating hour.

There are still many points to consider before using a predetermined rate. A direct cost is a price that can be completely attributed to the production of specific goods or services. A clearing account is used to hold financial data temporarily and is closed out at the end of the period before preparing financial statements. An account used to hold financial data temporarily until it is closed out at the end of the period. Harold Averkamp has worked as a university accounting instructor, accountant, and consultant for more than 25 years. The invoices for these costs were received, but only half of the bill was paid in June.

Since the company is not very labor intensive, use of machine operating hours as a cost driver seems appropriate. For example, overhead costs may be applied at a set rate based on the number of machine hours or labor hours required for the product. To remain operational, a manufacturing unit also incurs indirect or overhead costs. Rent, utilities, maintenance, warehousing and supervision are examples of indirect costs that cannot be allocated to a single unit of production but must be included in total production costs. The assignment of overhead costs to jobs based on a predetermined overhead rate. A predetermined overhead rate is often an annual rate used to assign or allocate indirect manufacturing costs to the goods it produces.

- It will have a huge impact on inventory and cost of goods sold.Rely on management estimationThis method relies on the management team who will try to make the financial statement look good.

- For example, the cost of Job 2B47 at Yost Precision Machining would not be known until the end of the year, even though the job will be completed and shipped to the customer in March.

- The base unit identification is critical for the accurate allocation which ultimately helps to identify the department-wise performance and issues if any.

- The goal is to allocate manufacturing overhead costs to jobs based on some common activity, such as direct labor hours, machine hours, or direct labor costs.

- Are all costs other than direct material, direct labor, or selling and administrative costs.

When this journal entry is recorded, we also record overhead applied on the appropriate job cost sheet, just as we did with direct materials and direct labor. Figure 2.6 „Overhead Applied for Custom Furniture Company’s Job 50” shows the manufacturing overhead applied based on the six hours worked by Tim Wallace. Notice that total manufacturing costs as of May 4 for job 50 are summarized at the bottom of the job cost sheet. Remember that overhead applied does not represent actual overhead costs incurred by the job—nor does it represent direct labor or direct material costs. Instead, overhead applied represents a portion of estimated overhead costs that is assigned to a particular job.

Predetermined overhead rate

•Some overhead costs, like factory building depreciation, are fixed costs. If the volume of goods produced varies from month to month, the actual rate varies from month to month, even though the total cost is constant from month to month.